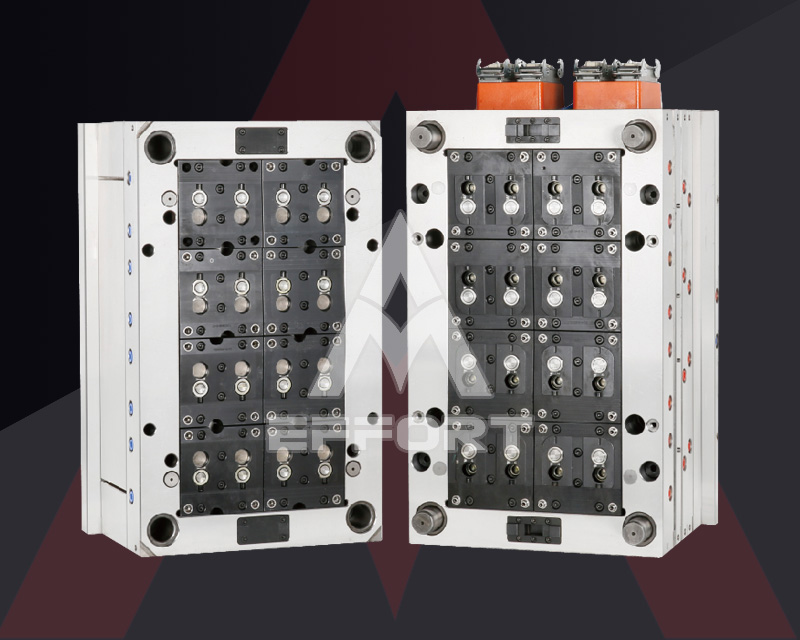

16 Cavities Bottle Cap Mould

Professional High Precision Free Plastic Mould Design Service 16 Cavity Cold Runner Flip Top Cap Mould For Different Bottles

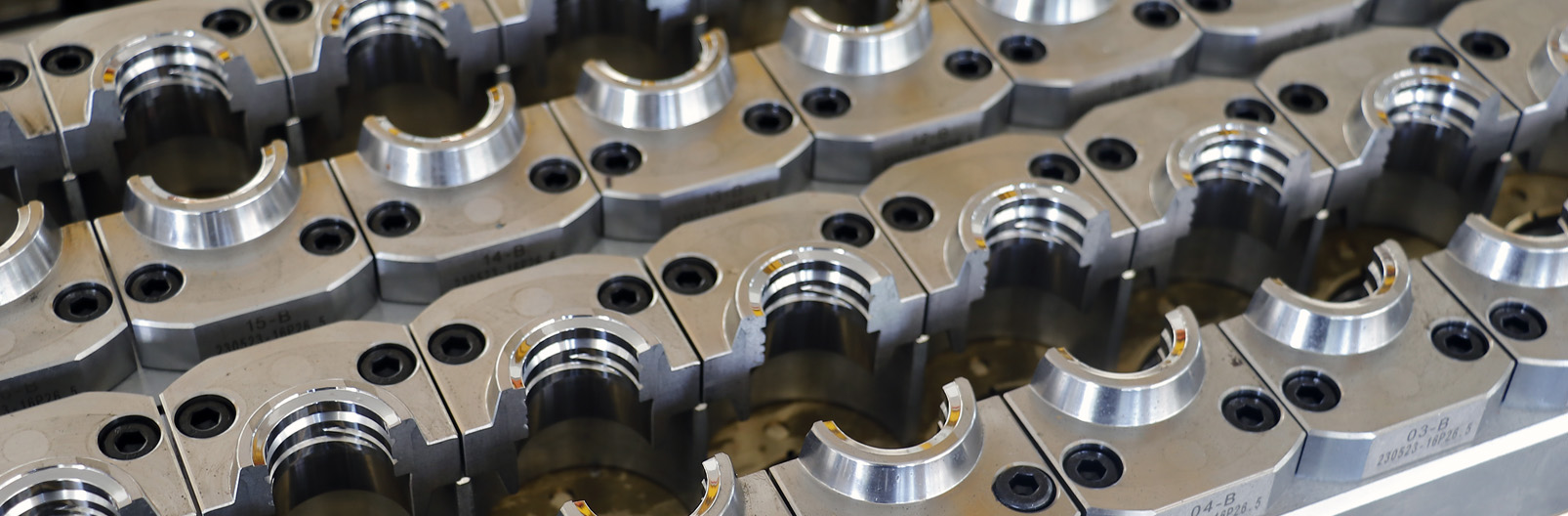

Adopt imported steel, like P20, 2316, S136 etc

Each cavity and core have independent cooling system, reduce recycle time.

Rational mold design to increase mold using time and get higher productive efficiency.

Precision processing equipment to ensure high production quality.

Vacuum hardening increase mold steel hardness to HRC62.

Electroplating processing makes whole mold shinny and rust-proof.

Professional High Precision Free Plastic Mould Design Service 16 Cavity Cold Runner Flip Top Cap Mould For Different Bottles

1. PP PE PET PC cap mold

2. Flip-top cap mold

3. Mould life 2 million shots

4. Cold runner or hot runner system

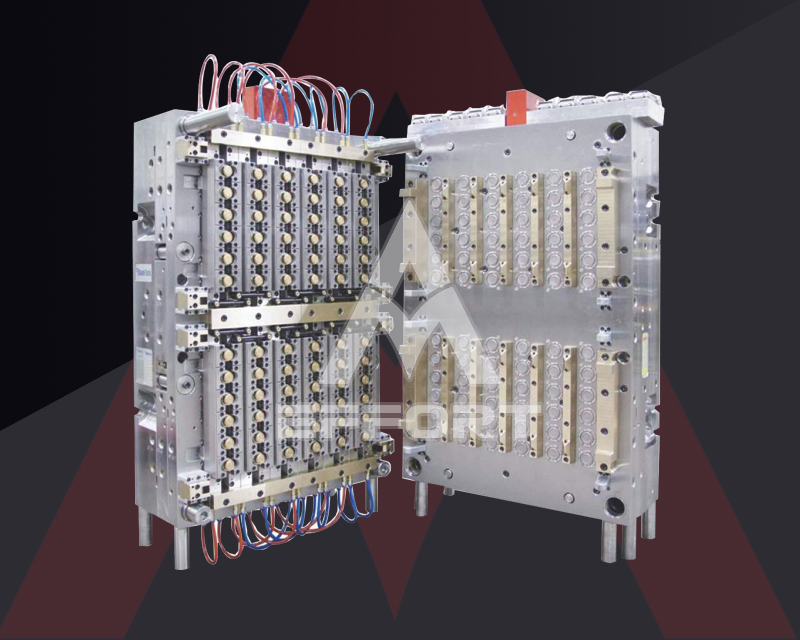

Flip Top Caps Molds

Automatic flip top cap Molds structure is more difficult than normal caps, the mold ejection system is special and have double steps. the cap closing success rate is very important to the Mould.

Effort is the cap Molds maker in China, who can make 24 cavities flip top caps mould with automatic closing system. Automatic production equipment is much more safer than human made. And it will help save cost in employee labors. Full automatic is international trend toward. If you want to improve your injection equipment, welcome contact me free. We are flip top caps mould China and looking for more and more partner all over the world.

Mineral Water Cap Molds

Plastic Mineral Water Cap Mould hallmarks include extremely fast cycle times, (sometimes less than 2 seconds). Mold cooling becomes extremely important to achieve these cycles as well as a smooth and even ejection of the parts from high cavitation molds which are some of StackTeck’s strengths.We specialized in designing and manufacturing plastic cap mold, PET preform mold, blowing mold with our own mould factory.AD/CAM/CAE system for designing and engineering mould products.We design and use standard moul frame and use pricision 3D printer and CNC tooling machine to make parts, in order to ensure the quality of the moulds. We also wholesale Plastic cap, other molds and service.

5 Gallon Bottle Cap Molds

aximize your 5 gallon water caps output - superior closure solutions for efficient 5 gallon water cap molds offered by shuanghao that has done a huge of different caps and closures projects, a division of Shuanghao Mould, are here for you! You will get the excellent 5 gallon water cap mold with full support from the cap design to mass production on your factory. shuanghao has delivered hundreds of high performance 5 gallon water bottle cap molds reputed among customers.

Plastic Handle molds

We take pleasure to introduce ourselves as the leading manufacturer and supplier of an excellent quality range of Plastic Handle Mould in the market. Offered mould is manufactured at our hi-tech manufacturing unit under the direction of highly accomplished professionals in compliance with the industry quality standards. To meet the set industry quality standard, offered Plastic Mould Handle is tested on various quality parameters by our experts. Further, these moulds are used for making various plastic handles .

Oil bottle Cap molds

Effort mould factory has been manufacturing oil bottle cap mould for many years. We devoted ourselves to cap mould, caps moulds injection mould, which are sold in more than 60 countries and areas.

We sincerely hope to establish good and long-term cooperation with customers all over the world! Pioneers in the industry, we offer Plastic Bottle Cap Mould Die, Plastic Cap Mould Die, Cap Mould Die and 28mm Plastic Cap Mould Die from China.

| Preform | Cavities | Structure | Dimensions | Weight | Array |

28/30mm caliber 15-35g | 4C | Needle valve | 420*260*450mm | 270kg | 1 |

| 6C | Needle valve | 530*260*450mm | 340kg | 1 | |

| 8C | Needle valve | 420*360*460mm | 380kg | 2 | |

| 12C | Needle valve | 530*360*460mm | 480kg | 2 | |

| 16C | Needle valve | 700*360*480mm | 660kg | 2 | |

| 20C pressure ports | Self-Locking | 820*340*370mm | 560kg | 2 | |

| 24C | Needle valve | 820*470*500mm | 1000kg | 3 | |

| 32C | Needle valve | 820*570*500mm | 1300kg | 4 | |

| 48C | Needle valve | 1094*620*587mm | 2200kg | 4 | |

| 72C | Needle valve | ||||

| 96C | Needle valve | 1250*1050*700mm | 5000kg | 6 |

| 38mm/64g | 6C | Needle valve | 480*400*533mm | 520kg | 2 |

| 8C | Needle valve | 550*400*533mm | 640kg | 2 | |

| 16C | Needle valve | 720*400*533mm | 840kg | 2 |

Oil bottle 46mm/90-110g | 4C | Needle valve | |||

| 6C | Needle valve | 530*420*550mm | 660kg | 2 | |

| 8C | Needle valve | 580*420*550mm | 730kg | 2 | |

| 12C | Needle valve | 720*370*550mm | 800kg | 2 |

| wide mouth 80mm/54g | 2C | Short self-locking | 350*280*380mm | 200kg | Side inclined guide pillar |

| wide mouth 100mm/69g | 4C | Short self-locking | 510*450*400mm | 500kg | Side inclined guide pillar |

| wide mouth 80mm/54g | 6C | Short self-locking | 570*410*400mm | 510kg | Built-in inclined guide column |

| wide mouth 120mm/60g | 8C | Short self-locking | 736*478*400mm | 780kg | Built-in inclined guide column |

| wide mouth 55mm/13g | 12C | Short self-locking | 800*320*330mm | 460kg | Built-in inclined guide column |