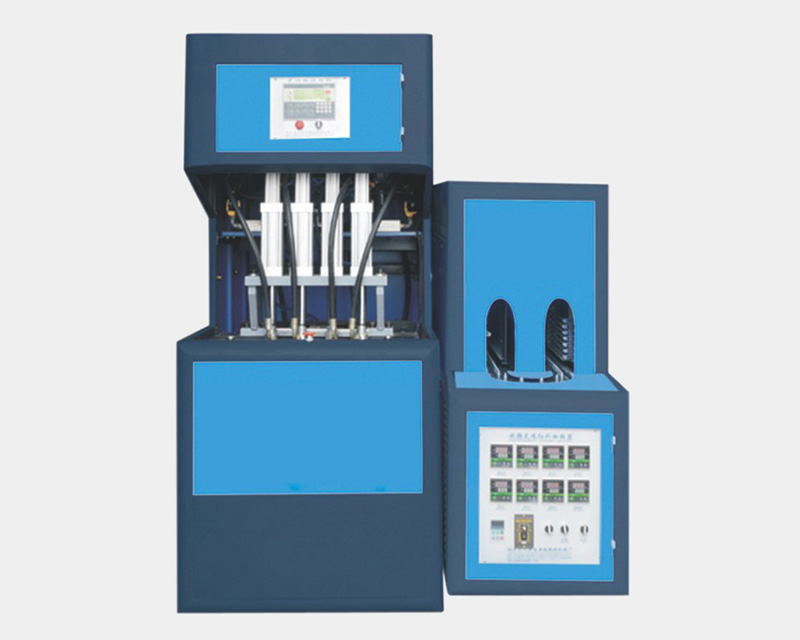

10L-1 5 Gallon Semi-Auto Blow Moulding Machine

Features:

1.Double crank arm for mold locking reaches high mold-locking strength and flexible action.

2.Use PLC for control(time relay control optional),easy repair,low cost with the time controllable accurately in 0.01S.

3.The air circuit consist of action and blowing , to satisfy the different air pressure demand of them.

4.The

far-infrared heater adopting a way of conversion self-rotating heating

and the revolution makes the heating uniform,fast and reliable.

5.Independent temperature control devices are provided for different heating lamps to ensure well heating effect of preforms.

6.The heating lamps can be adjusted according to preforms.

7.Only need one operator,no need be specially trained,easy installing and starting.

| ITEM | EFT-5L-2/ EFT-10L-1 |

| PRODUCT VOLEME | 5--10L |

| PRODUCT CAVITY | 2 |

| PRODUCTION CAPCITY | 5L-2CAVITY 800-900 10L -1 CAVITY 600-800PCS/HR |

| PRODUCT DIAMETER | 28-120MM |

| MAX DIN | 300MM |

| VOLTAGE POWER | 380V/3PH/50-60HZ |

| MIN AIR COMPRESSOR | 1.6CM3/3.0MPA |

| TEMPLATE SIZE | 480*660MM |

| MOLD THINKNESS | 350--420MM |

| CLAMPING FORCE | 80KN |

| OPERATING PRESSURE | 8-10BAR |

| BLOWING PRESSURE | 30BAR |

| MACHINE TOTAL POWER | 10-15KW |

| MACHINE WEIGHT | 1000KG |

| MACHINE SIZE (L*W*H) | 2.3*0.8*2M |

| HEATER POWER | 10KW |

| HEATER WEIGHT | 800KG |

| HEATER SIZE (L*W*H) | 2.7*0.6*1.7M |