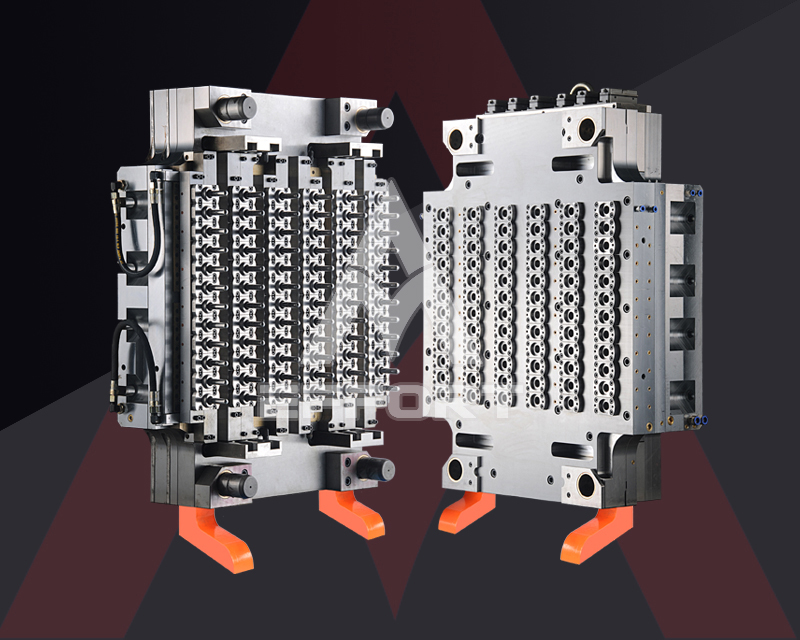

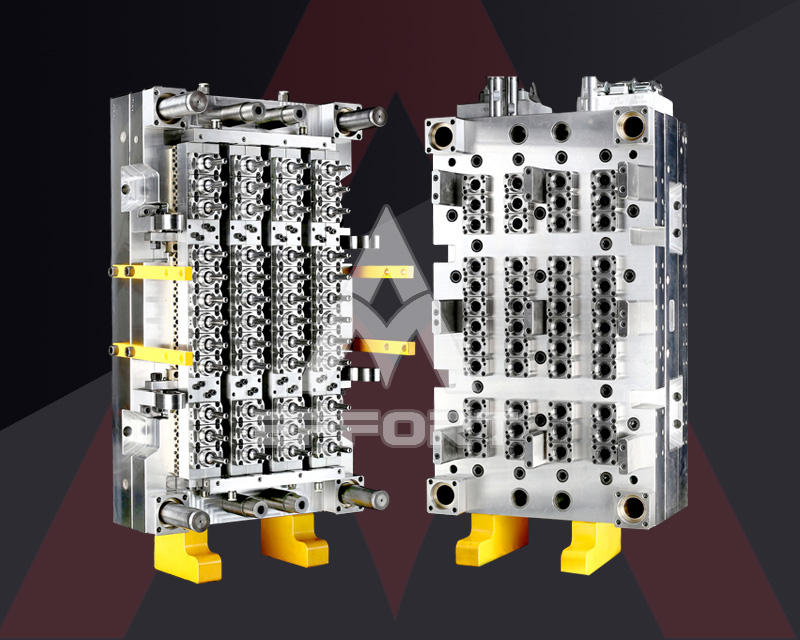

PET preform mould,72 cavity 28 mouth PET preform mould

PET preform mould,72 cavity 28 mouth PET preform mould for the preform with 30/25 Neck, is designed for the water drinks, the mold has balanced hot runner system with shut off valve gate, ensure there is no any stringing form on the injection gate of the performs. The cam roller design help the operator save the maintenance time of the molds. The PET preform mold is designed for Effort injection molding system. The weight of the preforms is 15.5g, Cycle time is 28 Sec with general PET screw injection molding machine. It reaches 14 Sec with 3 stage post cooling system.

PET preform mould features

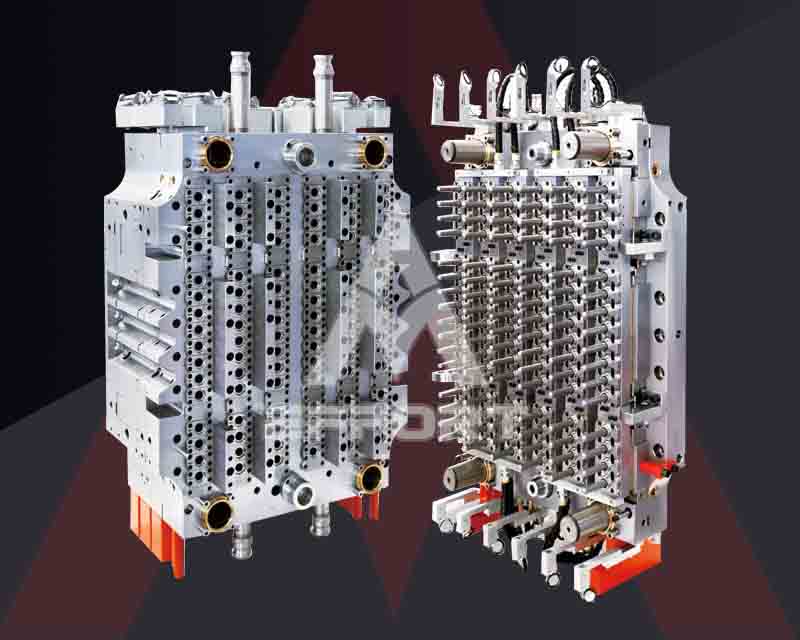

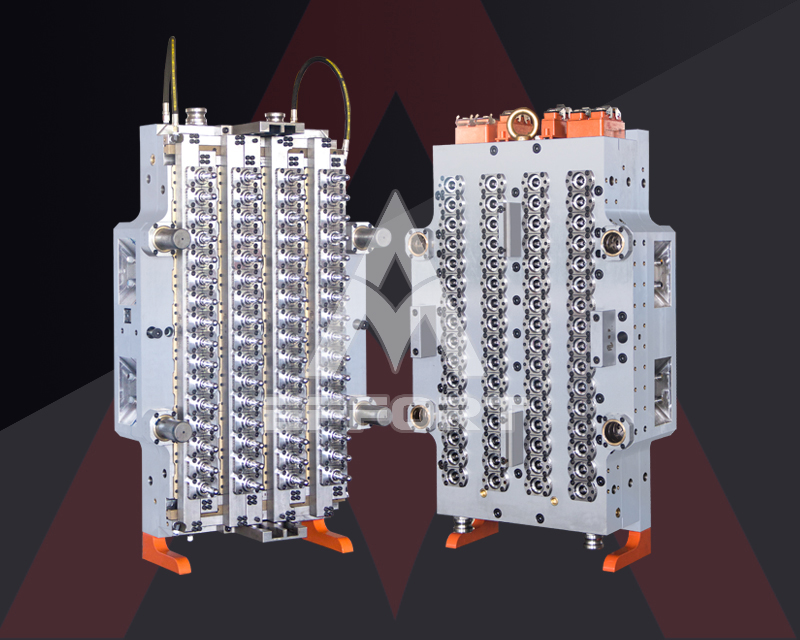

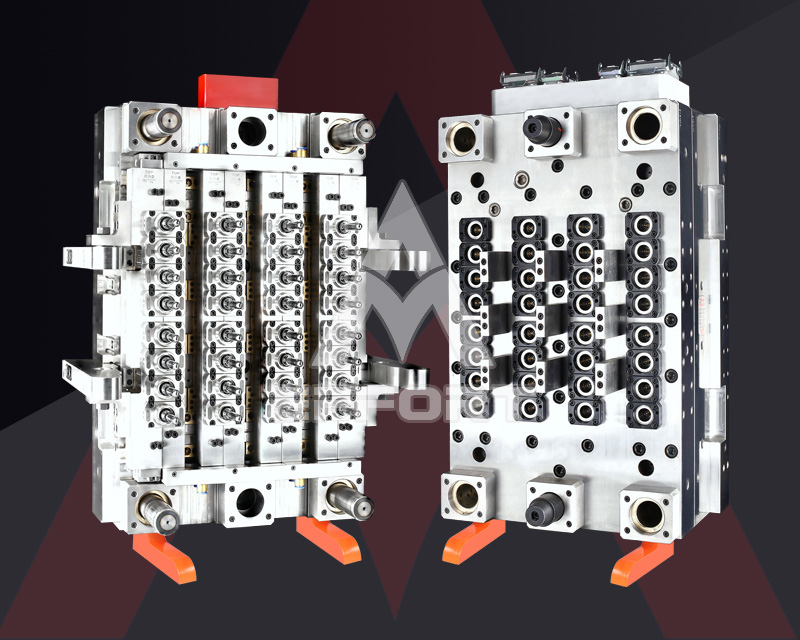

The hardness of the main parts of the mold reaches 48HRC, ensuring the service life of the mold. Standard cavity and core design ensure interchangeability. Maintenance-free guide rail type demoulding, + this structure has the characteristics of maintenance-free and low noise. Maintenance-free slider self-lubricating unit improves the service life of the slider. Two-way pneumatic needle valve design avoids drawing problems at the bottom of the preform. The optimized cooling water channel design effectively shortens the injection molding cycle of preforms. Computer analysis of flow channel fluid ensures the uniformity of multi-cavity preforms. An optional preform core coating is available that extends the life of the part.

72 Cavities PET Preform Mould for the preform with 30/25 Neck, is designed for the water drinks, the mold has balanced hot runner system with shut off valve gate, ensure there is no any stringing form on the injection gate of the performs. The cam roller design help the operator save the maintenance time of the molds. The PET preform mold is designed for effort injection molding system. The weight of the preforms is 15.5g, Cycle time is 28 Sec with general PET screw injection molding machine. It reaches 14 Sec with 3 stage post cooling system.

| PET Preform Mould Specification | |

| Mould name | 72 cavity preform mould for 30/25 Neck 11.5g Preform |

| Mould cavity | 72 cavity |

| Neck finish | 30/25 Neck finish |

| Preform weight | 11.5g |

| Insert materials | ASSAB FS136/Purpose made 632 |

| Mould plate | 4Cr13/P20(Preharden) |

| Hot plate | H13(Preharden) |

| Heating coil | Rotfil from Italy/Hotset from Germany |

| Copper nozzle | Beryllium bronze From Italy |

| Insulator | From USA DU PONT |

| Suitable injection molding machines | Husky, Netstal PET line, PET Master, General PET injection molding machine |

Product Description

Product DescriptionWe are among the pioneers in the industry, engaged in offering 72Cavity Pet Preform Moulds to our revered customers. The offered Preform Moulds are extensively utilized in the production of a variety of PET bottles and enable uniformity & dimensional accuracy for them. Premium quality raw materials and sophisticated technology are applied in the manufacture of these Preform Moulds.

Features:

Precise design

Heat treated

Corrosion resistance

Specifications:

Shaping Mode: Plastic Injection Mould

Product Material: Steel

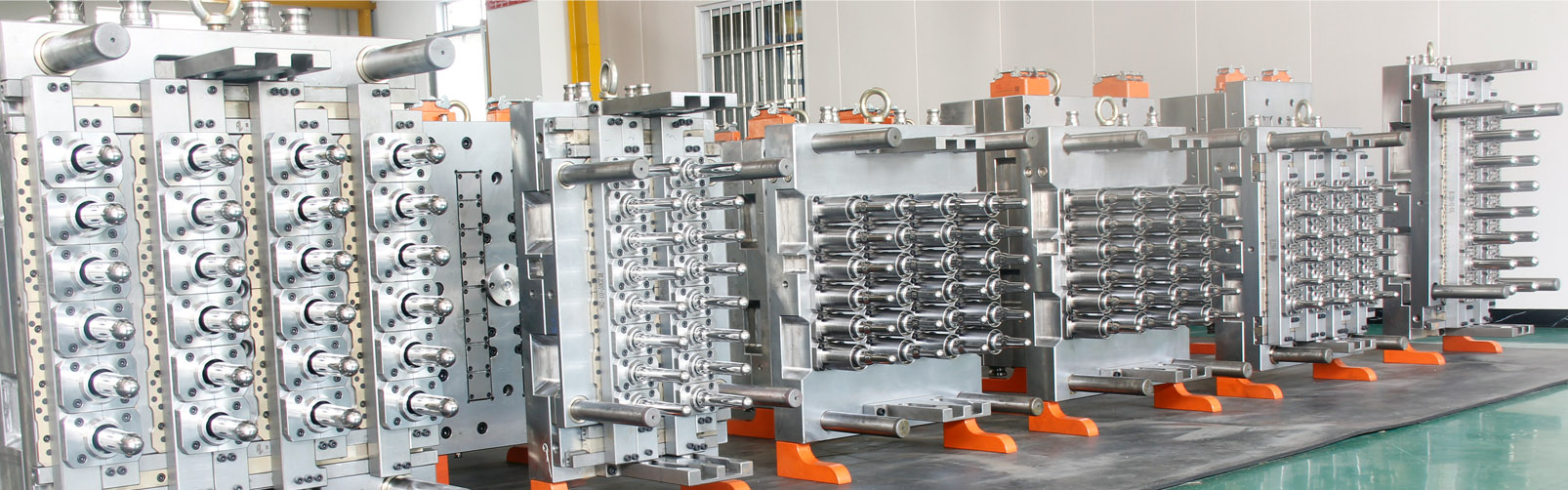

PET preform molds: From 1 cavity to 96 cavity

1.We are one of the most reliable companies in this domain offering PET Preform Mould with advanced mould design technology.

Multicavity: 1-8 cavity, 12 cavity, 16 cavity, 24 cavity, 32 cavity, 48 cavity, 56 cavity, 72 cavity and 96 cavity.

Neck finish:PCO, 1810,1881,30/25,29/25,38 ,ALASK, ROPP; Jar neck and others.

| Cavity Number | 22g Preform Length:94mm | 32g Preform Length:120mm | 42g Preform Length:130mm | |||

| Dimension(mm) | Weight(kg) | Dimension(mm) | Weight(kg) | Dimension(mm) | Weight(kg) | |

| 4(1*4) | 500*290*430 | 550 | 500*290*445 | 600 | 500*290*455 | 680 |

| 6(2*3) | 430*370*400 | 760 | 430*370*415 | 850 | 430*370*425 | 900 |

| 8(2*4) | 490*370*435 | 810 | 490*370*450 | 900 | 490*370*460 | 970 |

| 12(2*6) | 630*370*435 | 1020 | 630*370*450 | 1100 | 630*370*460 | 1180 |

| 12(2*8) | 750*370*480 | 1240 | 750*370*495 | 1350 | 750*370*505 | 1450 |

| 24(3*8) | 830*440*500 | 1880 | 830*440*515 | 1950 | 830*440*525 | 2060 |

| 32(4*8) | 830*580*515 | 2360 | 830*580*530 | 2250 | 830*580*545 | 2600 |

| 48(4*12) | 1065*580*525 | 2930 | 1065*580*540 | 3050 | 1065*580*555 | 3150 |

| 72(6*12) | 1140*830*560 | 4320 | 1140*830*575 | 4450 | 1140*830*580 | |

PET preform Mould Feature

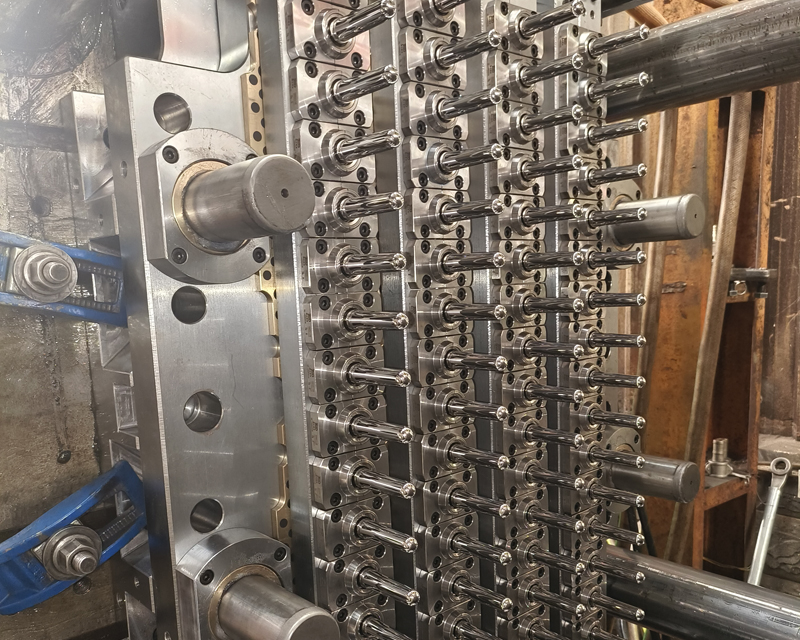

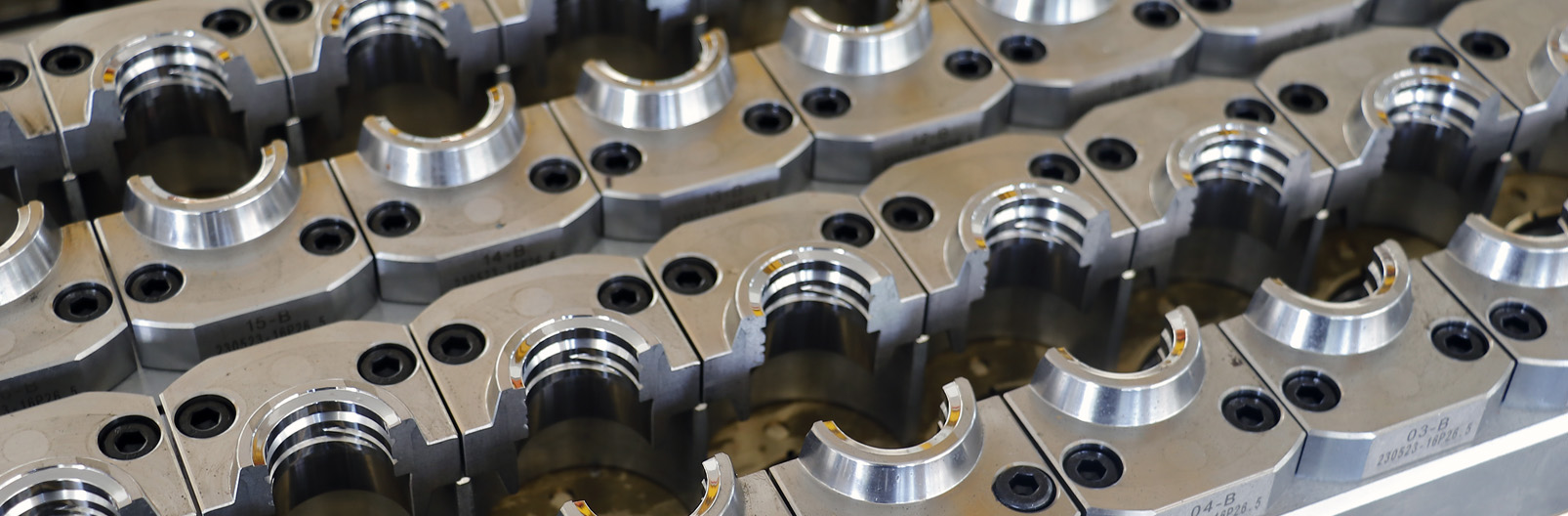

1. Mould plates are 4G13 or P20 stainless steel with pre-hardening process. Core, cavity and neck screw are made of S136 high Strength, anti-corrosive stainless steel. Mould plate is completed by one-time processing to ensure the concentricity of moulding hole and guide bush, guaranteeing the compact structure of mould.

2. Spiral cooling design for each single core and cavity, it helps to lessen the cycle time, improving production efficiency and saving costs. Opening/closing pulling plate adopts bearing slide type to drop the preform with realiable structure. And it is a highly integrated process of slider, pushing plate and ejection. All sliding parts surface inlaid self-lubricating copper alloys to ensure low friction effecient and strong wear-resistant.

3. Self- lock individually for each cavity to guarantee high precision and less defect of the final preform production as well as convenient disassembly.

4. Off-center adjustment system to ensure preform thickness difference < 0.10mm. Adopting double cone positioning principle guarantees high manufacturing precision to ensure the product without appearing flash, different size, irregular and other defects.

5. Experienced designers design preform mould with UG, Pro-E according to the clients sample; Preform thickness and height is reasonably and perfectly designed to ensure the final bottles weight light but feel hard.

6. Hot runner valve gate system is perfect used; No need to cut preform tail and it would save labor costs.

7. Hot runner system uses China advanced brand or imported hot runner system brand such as Yudo/Mastip/Hasco etc. Each cavity has independent temperature control and heater system. It will prevent the white defects on the preform and improve the qualtiy of plastic products.

8. Customer service: one year free warranty, life-long technical support service.

| Preform | Cavities | Structure | Dimensions | Weight | Array |

28/30mm caliber 15-35g | 4C | Needle valve | 420*260*450mm | 270kg | 1 |

| 6C | Needle valve | 530*260*450mm | 340kg | 1 | |

| 8C | Needle valve | 420*360*460mm | 380kg | 2 | |

| 12C | Needle valve | 530*360*460mm | 480kg | 2 | |

| 16C | Needle valve | 700*360*480mm | 660kg | 2 | |

| 20C pressure ports | Self-Locking | 820*340*370mm | 560kg | 2 | |

| 24C | Needle valve | 820*470*500mm | 1000kg | 3 | |

| 32C | Needle valve | 820*570*500mm | 1300kg | 4 | |

| 48C | Needle valve | 1094*620*587mm | 2200kg | 4 | |

| 72C | Needle valve | ||||

| 96C | Needle valve | 1250*1050*700mm | 5000kg | 6 |

| 38mm/64g | 6C | Needle valve | 480*400*533mm | 520kg | 2 |

| 8C | Needle valve | 550*400*533mm | 640kg | 2 | |

| 16C | Needle valve | 720*400*533mm | 840kg | 2 |

Oil bottle 46mm/90-110g | 4C | Needle valve | |||

| 6C | Needle valve | 530*420*550mm | 660kg | 2 | |

| 8C | Needle valve | 580*420*550mm | 730kg | 2 | |

| 12C | Needle valve | 720*370*550mm | 800kg | 2 |

| wide mouth 80mm/54g | 2C | Short self-locking | 350*280*380mm | 200kg | Side inclined guide pillar |

| wide mouth 100mm/69g | 4C | Short self-locking | 510*450*400mm | 500kg | Side inclined guide pillar |

| wide mouth 80mm/54g | 6C | Short self-locking | 570*410*400mm | 510kg | Built-in inclined guide column |

| wide mouth 120mm/60g | 8C | Short self-locking | 736*478*400mm | 780kg | Built-in inclined guide column |

| wide mouth 55mm/13g | 12C | Short self-locking | 800*320*330mm | 460kg | Built-in inclined guide column |