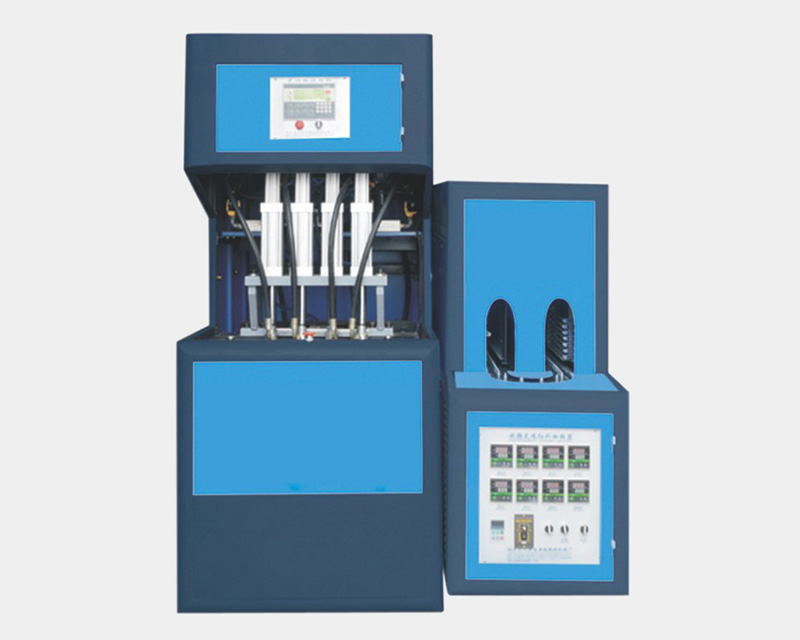

1 Cavity 10L Full Automatic Blow Moulding Machine

● Full servo motor is applied for all model machines, the servo motor advantage is fast and efficient.

● The blowing system adopts Parker blowing valve, SMC cylinder, servo helical tooth stretching, which is more stable and accurate speed.

● Mainpulator device, automatic preform feeding and bottle taking, which is fast and accurate.

● The heating system adopts infraed red wave tube, which has good heating performance, energy saving and consumption reduction.

| Specification | Eft-5L-2 | Eft-10-1 | Eft-10L-2 | Eft-20L-1 | Eft-20L-2 | |

| Theoretical Output | BPH | 1600-1800 | 700-900 | 1000-1500 | 600-800 | 800-1200 |

| Max bottle volume | L | 5 | 10 | 10 | 20 | 20 |

| Preform neck size | mm | 45-80 | 45-65 | 45-65 | 45-80 | 45-80 |

| Max bottle diameter | mm | 180 | 240 | 240 | 300 | 300 |

| Max bottle height | 350 | 430 | 430 | 500 | 500 | |

| Mould cavity No. | cav | 2 | 1 | 2 | 1 | 2 |

| Max heating power | kw | 100 | 115 | 108 | 225 | 135 |

| Installation Power | kw | 100 | 115 | 120 | 240 | 150 |

| Machine Size | m | 5.6x2.1x2.1 | 4.5x1.6x2.2 | 4.8x2.1x2.2 | 5.0x1.8x2.2 | 5.8x2.1x2.2 |

| Machine weight | Ton | 5.5 | 4.5 | 5.5 | 5.5 | 6.5 |