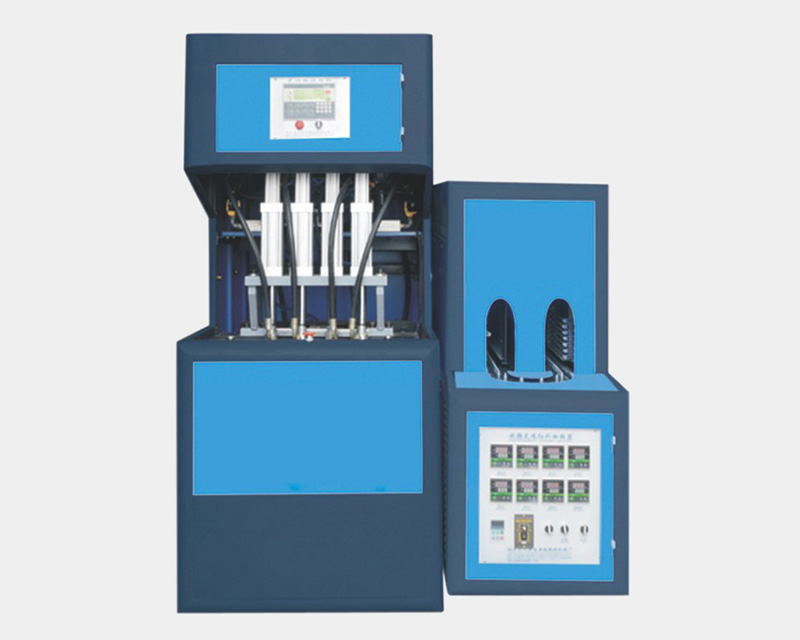

2 Cavity 5L Full Automatic Blow Moulding Machine Manufacturers

● Full servo motor is applied for all model machines, the servo motor advantage is fast and efficient.

● The blowing system adopts Parker blowing valve, SMC cylinder, servo helical tooth stretching, which is more stable and accurate speed.

● Mainpulator device, automatic preform feeding and bottle taking, which is fast and accurate.

● The heating system adopts infraed red wave tube, which has good heating performance, energy saving and consumption reduction.

5L 2 cavity full automatic plastic bottle blow moulding machine for 1L to 7L bottles

5L high speed full automatic pet bottle blower can produce different shapes from 1L to 7L water bottles,edible oil bottles and other plastic PET containers. High speed,low defect rate,stable running and easy operation.

Machine Parts

a.PLC controller touch screen : Mitsubishi (Japan)

b.Pneumatic parts:AIRTAC(TAIWAN)

c.Controller of stretch ,shift ,clamping servo motor : Mitsubishi(Japan)

d.Other parts are world-famous brands

| Specification | Eft-5L-2 | Eft-10-1 | Eft-10L-2 | Eft-20L-1 | Eft-20L-2 | |

| Theoretical Output | BPH | 1600-1800 | 700-900 | 1000-1500 | 600-800 | 800-1200 |

| Max bottle volume | L | 5 | 10 | 10 | 20 | 20 |

| Preform neck size | mm | 45-80 | 45-65 | 45-65 | 45-80 | 45-80 |

| Max bottle diameter | mm | 180 | 240 | 240 | 300 | 300 |

| Max bottle height | 350 | 430 | 430 | 500 | 500 | |

| Mould cavity No. | cav | 2 | 1 | 2 | 1 | 2 |

| Max heating power | kw | 100 | 115 | 108 | 225 | 135 |

| Installation Power | kw | 100 | 115 | 120 | 240 | 150 |

| Machine Size | m | 5.6x2.1x2.1 | 4.5x1.6x2.2 | 4.8x2.1x2.2 | 5.0x1.8x2.2 | 5.8x2.1x2.2 |

| Machine weight | Ton | 5.5 | 4.5 | 5.5 | 5.5 | 6.5 |